Unraveling the World of Packaging Foam: Types and Versatile Applications

Packaging foam serves as a crucial component in ensuring the safety and protection of a wide array of products during transit, storage, and handling. Let’s delve into the diverse types of packaging-foam and their multifaceted applications across various industries.

Understanding Foam Types

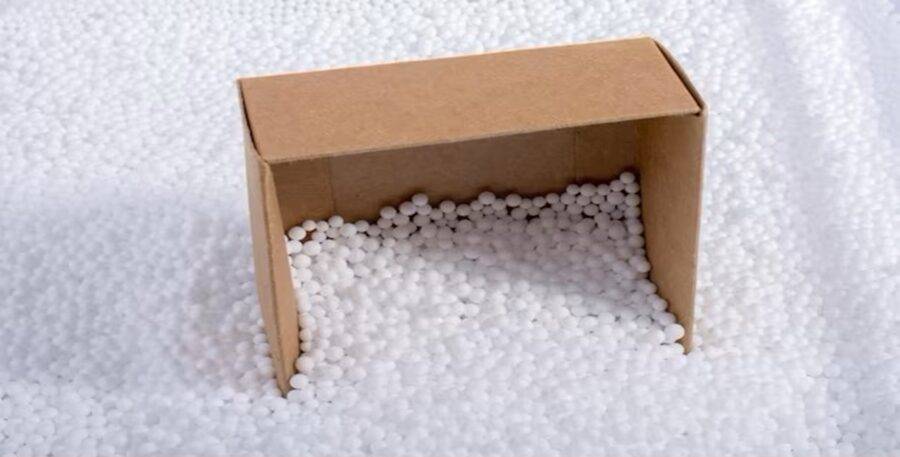

1. Expanded Polystyrene (EPS)

EPS foam, known for its lightweight and insulating properties, is widely used in packaging fragile items such as electronics, appliances, and medical supplies. Its shock-absorbing capabilities make it ideal for safeguarding delicate products.

2. Polyethylene Foam (PE)

PE foam, characterized by its flexibility and resilience, is extensively employed for cushioning and shock absorption in packaging. Its non-abrasive nature makes it suitable for protecting surfaces prone to scratching or damage.

3. Polyurethane Foam (PU)

PU foam, recognized for its adaptable nature, molds itself to the shape of the packaged item, providing a custom-fit cushioning solution. Its versatility makes it an ideal choice for custom packaging and specialized product protection.

Applications Across Industries

Electronics and Technology: It plays a vital role in securing and cushioning sensitive electronic devices, preventing damage from impact and vibration during shipping and handling.

Medical and Pharmaceutical: In the medical industry, foam packaging ensures the safe transport of fragile medical equipment, laboratory supplies, and pharmaceutical products, maintaining their integrity and sterility.

Automotive and Aerospace: Foam packaging contributes to the protection of delicate automotive and aerospace components, safeguarding them from potential damage caused by handling, shipping, and environmental factors.

Consumer Goods: From fragile glassware to intricately designed products, foam packaging provides a cushioning layer that prevents breakage and surface damage, enhancing the overall customer experience.

Environmental Considerations: Efforts are underway to develop sustainable foam materials, including biodegradable and recyclable options, aligning with the growing focus on environmental responsibility and the circular economy.

Innovations and Future Trends:

Advancements in foam technology are driving the development of foam solutions with enhanced protective properties and reduced environmental impact, marking a shift towards eco-friendly and innovative packaging materials.

Read More from our study Packaging Foam Market report and request for a free sample report to know more.

Conclusion:

Packaging-foam, in its various forms, continues to be an indispensable asset in ensuring the safe and secure transportation and storage of diverse products. The evolving landscape of foam materials is poised to bring about more sustainable and high-performance solutions, catering to the dynamic needs of modern packaging requirements across industries. Whether it’s protecting delicate electronics, safeguarding medical equipment, or ensuring the safe delivery of consumer goods, the role of packaging-foam remains instrumental in preserving product integrity and ensuring customer satisfaction.

By embracing innovation and sustainable practices, the packaging-foam industry is set to redefine product protection and environmental stewardship, shaping the future of packaging solutions.

– Analyst Team

IHR Insights

inquiry@ihrinsights.com